TRADITIONAL TEXTILES OF ANDHRA PRADESH

One of India's 29 states, Andhra Pradesh is located on the southeast coast of the country. The state is the eighth-biggest by area, the tenth-largest by population, and it boasts one of the longest coastlines along the Bay of Bengal. It is also home to some of the world's largest mineral deposits and is very prosperous in the agricultural and textile industries.The state's collection of clothing and jewellery designs was improved by innovations in the textile and jewellery manufacturing industries. The best methods for producing and dying cloth are practiced in this state, where they also have a long history. There are many different counts available for cotton fabrics of all varieties, ranging from light weights to thick coarse fabrics. The culture and traditions of Andhra Pradesh have been profoundly impacted by these many ranges. Andhra Pradesh's culture and legacy are extraordinarily rich thanks to this extraordinary variety.

Andhra Pradesh's traditional attire is not all that dissimilar from those of other southern states in the union.

Some of the world's most exquisite ancient clothing, fashion, and dying practices may be found in Andhra Pradesh. A strong fashion tradition that has withstood the test of time is formed by its prolific cotton production, inventive plant dye extraction history, diamond mining, pearl harvesting, and jewellery traditions. Countless famed gems, including the Koh-i-Noor and Hope Diamond, are descended from the ancient Kollur mine. Eight of the ten most valuable pieces of jewellery on earth today have ties to Andhra Pradesh, which up until the establishment of the diamond mines in Rhodesia, Africa, maintained a virtual monopoly on the world jewellery market.This three thousand year old fashion legacy is seen in the Langa-Voni (Half saree), Kalamkari, Venkatagiri. Fine instances of this historic tradition's ongoing evolution include Vaddaanam, Aravanke, Kashulahaaram, Buttalu, and many standard gold jewellery styles.

TRADITIONAL DRESS OF AP

In Andhra Pradesh, men typically don a dhoti and a kurta. Dhotis were worn by both men and women in Andhra Pradesh prior to the 14th century. But as time went on, their dhotis became longer and longer, and eventually they began utilising another piece of cloth to wrap around their shoulders. Later, the additional piece of fabric was sewn together to create a sari. The sari is a long piece of fabric that is typically 512 metres or 6 yards long. The excess is draped across the torso and over the shirt of the wearer.

Langa Voni

In south India, young girls and women typically dress in a two-piece or half-saree called a langa voni. It is made up of a shirt, a skirt, and a dupatta. Prior to marriage or before entering puberty, girls don Langa Voni. They may also choose to forgo the dupatta.

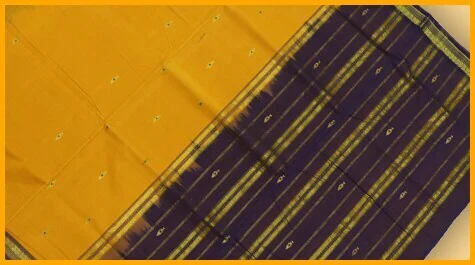

VENKATAGIRI SARI

The Venkatagiri Sari is a type of sari made in the Tirupati region of the Indian state of Andhra Pradesh's Venkatagiri. The intricate weaving of Venkatagiri saris is renowned. The villages of Sengunthapuram, Variyankaval, Elaiyur, Kallathur, Andimadam, and Marudhur also produce saris in this manner. The sari has a long history that begins in the early 1700s under Venkatagiri's dominion. The Nellore Velugoti dynasty, as well as the Bobbili and Pithapuram dynasties, all supported them. They were mostly woven during those times for queens, royal ladies, and Zamindaris. Weavers received grains for a year in exchange.

"With its distinctive Jamdhani work, Venkatagiri has established a distinctive position in the production of beautiful cotton saris that are well-known worldwide. existence is due to an ancient weaving process that displays exceptional artistry. Nobody else can create captivating figurative artwork that appears on both sides of materials, and this is why venkatagiri sari has gained international acclaim.

Materials for manufacturing, such as cotton hanks, silver and gold zari, and naphthol and vat dyes

Cotton purification: Cotton hanks are boiled to eliminate some impurities, then they are soaked overnight, cleaned, and prepared for dyeing.

- When dying saris, bleaching is used on white ones, and vat and naphthol dyes are used on coloured ones.

- Removal of excess dye involves soaking coloured or bleached yarn in boiling water while using certain strategies to reduce colouring.

- Following the aforementioned procedure, the yarn is dried on bamboo sticks in hank shape.

- Hank yarn is wound into warp and weft using charka, shift bamboo, and bobbins. While a pirn is used to create the weft.

- Street sizing, warp extension, and rice conjee spraying assure proper weaving, which is followed by drying.

- The process of weaving uses the Warp and Weft method, which is occasionally superseded by Jacquard weaving.

- Design conception incorporates two processes: the Human Element and the Graph Design of Paper

- Folding and cutting - Woven fabric is trimmed to meet product demand.

- Sarees are examined by the master weaver to identify and correct defects.

- Using a showroom display to sell sarees is marketing.

MANGALAGIRI

In Mangalagiri, a town in the Guntur district of the Indian state of Andhra Pradesh, handcraft weaving is used to create Mangalagiri sarees and fabrics. Pitlooms are used to weave combed yarn into the Mangalagiri cloth by interlacing the warp and woof threads. The procedure of dying is then applied to the fabric. Another feature of the cloth is the Nizam pattern. According to several inscriptions discovered in this area, weaving has been a profession for at least 400 years. Weavers experienced a period of migration under Qutub Shahi's authority as a result of an increase in taxation.Mangalagiri saris are a special type of sari made of cotton with the most distinctive elements like zari on the border and no woven patterns on the body. The saris are worn by devotees for religious purposes as the town is also home to the Lord Narasimha Temple.

UPPADA JAMDANI SAREES

A silk sari style known as the Uppada Jamdani Sari is produced in the Indian state of Andhra Pradesh's Uppada of the East Godavari district. Lightweight Uppada Jamdani saris are well-known. In the Uppada Jamdani Sari, the name Jamdani is spelled in Persian, where Jam is the word for flower and Dani is the word for vase. Uppada Jamdani saree weaving requires at least two to three weavers to devote 10 hours per day to the process, which takes roughly 10 to 60 days. Purest lace (silver zari frequently coated in melted gold) and the best Bengaluru-area silk are used by the weavers. Saree weaving requires planning the design, weaving silk threads together, using a loom, etc. In and around Uppada and Kothapalli, there are over 3000 looms making Jamdani sarees.

Women make up to 40% of the local weavers. A sari is entirely handwoven and is created in a week to a fortnight using cotton for the body and silk for the pallu. The fabric is created by weavers to be foldable and matchbox-sized. Different designs include geometric, floral, and leaf patterns, among others. The unique feature of Jamdani sarees is that they are significantly lighter and have designs on both sides than Kanchi and Dharmavaram brands.

CHIRALA SAREES

It was also known as "Kshirapuri," and it was a coastal town located in the Prakasam District of the Andhra Pradesh state. Commonly known as 'Mini Mumbai' for its textile market,Handlooms are well-known in the town of Chirala. As the years went by, the town became well-known for its superb handloom sarees, which are renowned for their softness and durability. Chirala, which in Telugu means "saree," finally replaced the original name of the town. This village's primary industries are paddy cultivation and handloom weaving.

The Chirala weavers create cotton sarees, seico sarees, which are a delicate fusion of cotton and silk fibres, and kuppadam (Gadwal type). Typically, the "Fly Shuttle Loom" is employed in Chirala. A noteworthy design element of Chirala sarees is hand butta, where colours are manually placed in-between the zari design. Hand butta materials are soft and most pleasant to wear, which suit all climates. The weavers from communities in places like Devanga, Padmasali, and Pattusali carry on this creative tradition.

KALAMKARI OF MACHILIPATTINAM

In Andhra Pradesh, kalamkari is a highly regarded technique for hand-painting or block-printing cotton textiles and paintings. It is a technique for painting cotton fabrics using a kalam, or pen, in which the flow of colour on the fabric is controlled by a bamboo skewer with a pointy tip. Persian terms qalam (pen) and kari are the source of the name (craftmanship). For this type of art, Andhra Pradesh is well-known worldwide.

Pedana Kalamkari, commonly referred to as Machilipatnam style of Kalamkari work, is the process of block-painting a cloth with vegetable dyes. It is manufactured in the Krishna district of the Indian state of Andhra Pradesh's Pedana, a town close by to Machilipatnam. The Golconda Sultanate used this form of art as it developed under the Mughal Dynasty. Wall hangings and apparel items including bedsheets, curtains, and saris are among the various textile products made from this type of work. A wall hanging from the fifteenth century is still on display at the Victoria Museum in London.One of the two Kalamkari work styles that can be found in India is the Machilipatnam style; the other is the Srikalahasti form. Vegetable dyes are primarily used, and they are applied to the fabric using wooden blocks. Geographically, the only places where Machilipatnam Kalamkari is produced are Pedana town and the nearby villages of Machilipatnam, Polavaram, and Kappaladdi in Krishna district's Guduru mandal.

KALAHASTHI KALAMKARI

Srikalahasti Kalamkari is a type of Kalamkari craft that entails hand-painting a fabric with coloured dyes. It is made in Srikalahasti, a district of Tirupati, Andhra Pradesh, India. The Vijayanagara Empire ruled during the Kalamkari's existence. Two sorts of pens are used: one is made of bamboo for drawing and the other is for writing. Only natural dyes, derived from flowers and plants, are used in the colouring process. Seventeen steps total, including block production, fabric treatment, printing, washing, etc., are involved in the entire process. The Srikalahasti style is mostly employed to depict religious mythology and epic tales on textiles, and its saris are renowned for their borders and pallus.

A professional training on Kalamkari painting is provided by Tirumala Tirupati Devasthanams' Sri Venkateswara Institute of Traditional Sculpture and Architecture (SVITSA) for the development of emerging artists. The Andhra Pradesh Economic Development Board had charge of promoting historical art, addressing industrial issues, developing skilled labour, and enhancing export revenue creation.

BANDARULANKA AMALAPURAM SAREES

The Bandarulanka village, from where these particular sarees take their name, is where they first appeared. In the Indian state of Andhra Pradesh's East Godavari district, in the Amalapuram Mandal, is the town of Bandarulanka. Since ancient times, this town has gained fame for producing and making exquisite hand-loomed sarees. Bandarulanka sarees are reputed to be among the most comfortable and reasonably priced sarees available. In this village, there are many highly accomplished and talented weavers and artists whose families still rely on the creation and weaving of Bandarulanka sarees.

WEAVING

The heritage and methods of weaving have also been handed down through the generations. These sarees come in a broad range of colours and have rich, striking borders and booti designs. The pattern also incorporates zari embroidery to enhance the fabric's richness. Around 1800 A.D., Arunachal Pradesh is when the Bandarulanka sarees first appeared. Despite the fact that no literature or references specifically date the creation and heyday of the Bandarulanka saree.

In order to satisfy the needs, demands, and preferences of both urban and rural women, the Bandarulanka Saree is a simple yet attractive cotton saree that is made using an 80 count yarn. It is available in a variety of colourful colours and tones, ranging from pastel to dark shades. These are primarily made by elderly (45–60 year old) weavers.

A Bandarulanka saree costs between 400 and 1000 rupees.

The Bandarulanka Saree is a great option for every season, occasion, or event because it is composed of cotton. The fabric allows air to travel through, which keeps it cool. This property is known as breath-ability. The cloth is very gentle on the skin and guards against all skin rashes.

Therefore, these sarees are a need for any woman looking to cover herself in a straightforward, distinctive, and stunning saree.

KUPPADAM SAREES

India's Andhra Pradesh State is renowned for its fine handloom products and its inventive and hardworking weavers. They are renowned for creating bespoke sarees with elaborate and unusual motifs. One such invention is "Kuppadam Sarees," which was made by the state's "Chirala Community" and became quite famous in 2002. This handloom craft utilises a unique interlocking pattern called "Kupadam" on the weft of fabric weaving. As a result, the art form is known as "Kuppadam." The softness and hardness of the fabric are determined by the count utilised in the weaving.For soft woven sarees, the counts are employed up to 120 (length) - 120 (breadth). These sarees are especially used during pujas and other religious occasions since the borders typically have a temple pattern. Without Kuppadam Sarees, religious ceremonies and festive occasions are deemed insufficient in Andhra Pradesh.

DHARMAVARM PATTU SAREES

Handwoven paavadas and sarees made of mulberry silk and zari from the Dharmavaram region. They are made at Dharmavaram, a district in the Indian state of Andhra Pradesh. The Silk City of Andhra Pradesh is this city. Dharmavaram is a hub for 100% pure silk sarees. The weaving industry is essential to the community's economy.In the years 1153-54 AD, Kriya Shakthi Vodavaru Swamy gave the name Dharmavaram to honour his mother, Dharmambai. By the 19th century, the handloom silk industry had become the primary industry. The patterns of Dharmavaram saris are painted on the roof walls of Lepakshi Temple and Latha Mandapam.

Due to the number of mulberry trees nearby, which serve as a natural breeding site for wild silk worms, the town naturally adapted to silk weaving. By the late 1800s, mulberry silk The sheer brilliance and elegance of the weaving brought Dharmavaram sarees recognition on a national scale. The weavers developed over time to include all colours, themes, designs, and decorations to keep up with the changing times and expand their clientele. Originally woven as wedding sarees, in tones of red and yellow. To help the artisans fulfil the demands of a worldwide market, the procedure has been partially automated today. Even though these sarees are less than a century old, saree connoisseurs have made them a solid favourite.

One of the most religiously and ceremonially acceptable sarees is the Dharmavaram saree. As a result, these feelings are the focus of the majority of the motifs. The most well-liked patterns feature peacock feathers and peacock themes. Then come the patterns for elephants, stars, and Brahmakamals. Temple architecture has served as a sufficient source of inspiration, and these designs are frequently seen on saree pallus. These sarees have a distinctive, self-printed, gold-plated border. Motifs also rely on the skill and judgement of the weavers.

The majority of Dharmavaram sarees are constructed of heavy silk, hence expert dry cleaning is strongly advised. To maintain lifespan and durability, care should be taken to preserve and store these sarees properly, away from a wet environment.

Good Post

ReplyDelete